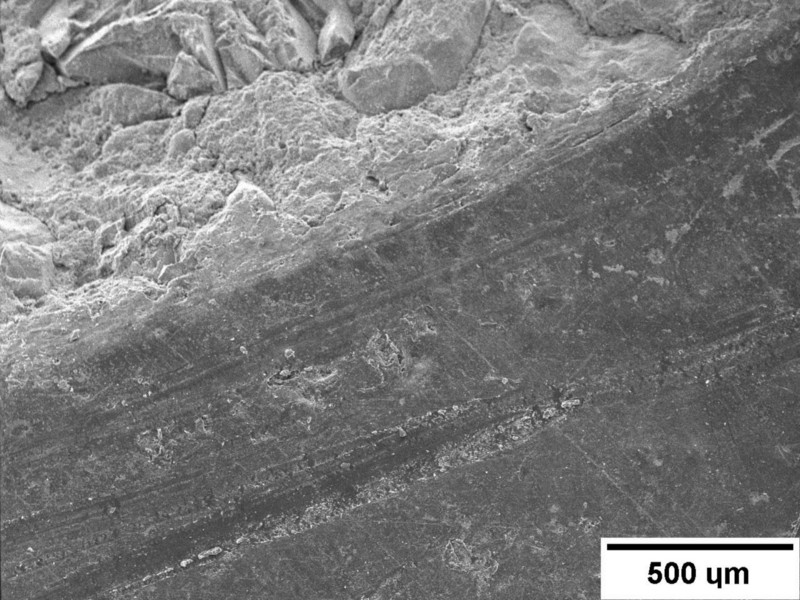

Another parameter that impacts the abrasion resistance of concrete is the surface mortar and secondary concrete layer of the concrete surface. Both are directly affected by wear and it is important to ensure these materials are given ample opportunity to hydrate and not be hampered by plastic shrinkage and the associated cracks that are developed. The above image shows an Electron Microscope Image of the Topside of the Trough from a Concrete Sample Tested by ASTM C 779, Procedure C. Upper left corner is the top of the concrete slab and the bottom right corner is the top of the trough.

Plastic Shrinkage

Plastic shrinkage includes those cracks that appear at the surface and secondary layers of concrete between the time that the concrete is placed and its initial set (penetration strength of 500PSI). The cracking takes place while the concrete is still in its plastic state. ACI recognizes four modes of plastic shrinkage at the macroscopic level. Besides being aesthetically displeasing these cracks can act as weak planes and have locations of reduced durability[1]. Furthermore, Neville defines that plastic shrinkage increases the permeability of the concrete and reduces the resistance to abrasion[2].

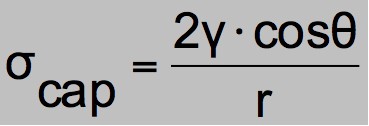

Weiss et al, show in their examination of plastic shrinkage that after the first phase (evaporation of surface water) gel pores of cement paste will consolidate due to the following properties in the Young-Laplace relationship:

Where sigma, cap is the pressure felt on the gel pores due to the surface tension, gamma of the pore fluid, its contact angle theta, and radius of gel pore, r [3]. Lura et al., shows that as the evaporation continues pore size will decrease due to the shape of the pore[4]. Here in lies the cause of plastic shrinkage, the increase in stress overcomes the strength of the curing concrete body. The stress at the surface and secondary layers of the concrete becomes a tensile stress and cracks occur. The method by which to mitigate these cracks is two fold.

As Lura et al., shows all concrete reacts to plastic shrinkage similarly within the first 45 to 60 minutes[5]. Within this time the surface water of a placed slab evaporates and plastic shrinkage ensues.

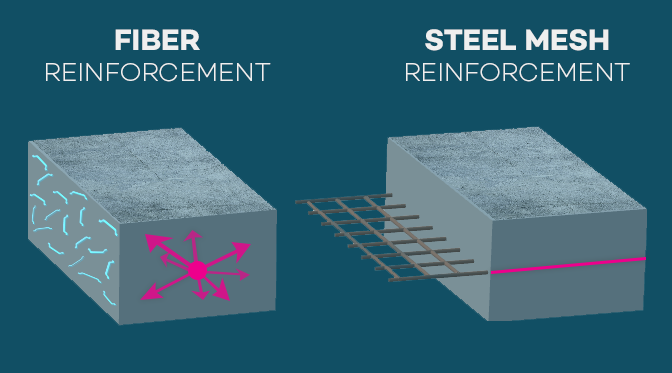

One method to moderate the impact of surface evaporation is through the use of micro fibres and cellulose fibers (Microforce and UltraFiber500)

Loss of water at the surface can only be moderated by either soaking the specimens in a layer of water or covering the surface with a continuous fog or an impermeable layer. All slabs used in the experiments were covered prior to the finishing process. Therefore all the slabs were allowed to be affected by the initial surface evaporation process. The relative humidity of the laboratory was kept at 40% (+/- 2%) for the duration of curing. The second method to control is by using a Shrinkage Reducing Admixture.

As shown in previous sections, the stress of the concrete gel is affected by the size of the pore as the evaporation process evolves. The gel pore radius is difficult to control as is the surface contact angle of the pore fluid. By reducing the surface tension of the fluid, the pressure developed by the capillary can be reduced.

[1] Lura P., et al. Influence of Shrinkage-Reducing Admixtures on Development of Plastic Shrinkage Cracks. ACI Materials Journal. March-April 2007. P 187.

[2] Neville A. Properties of Concrete. Prenctice Hall. 4th Edition. 2005. P 319.

[3] Lura P., et al. Influence of Shrinkage-Reducing Admixtures on Development of Plastic Shrinkage Cracks. ACI Materials Journal. March-April 2007. P 191.

[4] Lura P., et al. Influence of Shrinkage-Reducing Admixtures on Development of Plastic Shrinkage Cracks. ACI Materials Journal. March-April 2007. P 191.

[5] Lura P., et al. Influence of Shrinkage-Reducing Admixtures on Development of Plastic Shrinkage Cracks. ACI Materials Journal. March-April 2007. P 191.