Increased Load Bearing Capacity

Substantially Reduces Construction Time

HOW IT WORKS

Premium Reinforcement

It is well known that an addition of fibres to concrete is able to improve their tensile strength, fracture energy absorption and load bearing capacity. The fibre contribution is mainly reflected when the concrete cracking initiates and often enhances the post-cracking behaviour due to the improved stress transfer provided by the fibre bridging of the cracked sections. The most important parameter of fibres is their ability to transfer stresses across cracked sections rather uniformly.

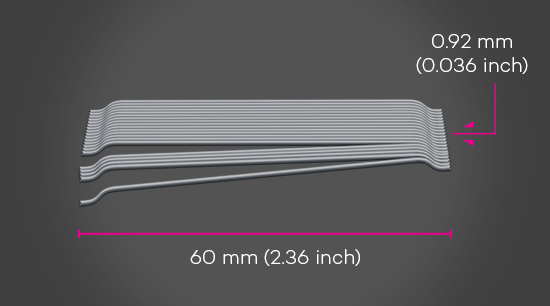

PROFORCE® Hookend Fibres are individual unit steel fibre with water-soluble adhesive substances in a bundle to increase fibre dispensability and minimise fibre balling.

PROFORCE® Hookend Fibres can replace all conventional secondary reinforcing methods for concrete or can be used in combination with them.

PROFORCE® Hookend Fibres are certified to CE mark and structural use (system 1) according to European Standard and are manufactured under ISO 9001 and ISO14001 certification.

Key Information

Specifications

All the details you need.

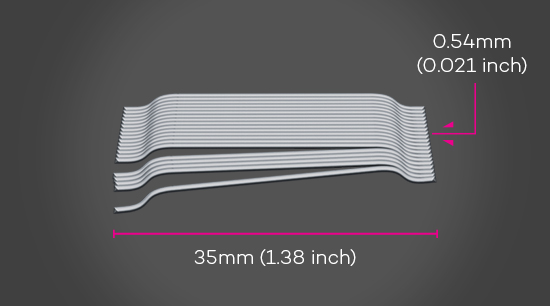

PROFORCE® 35

Premium Level Hookend Fibre

Downloadable product information, technical data sheets, MSDS and architectural specifications.

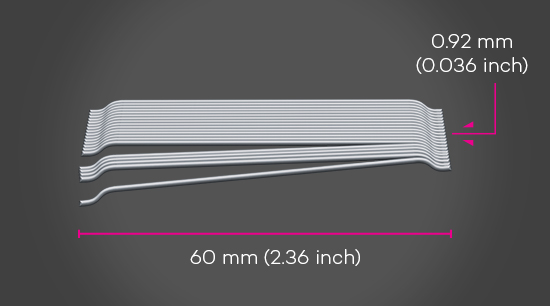

PROFORCE® 65

Premium Level Hookend Fibre

Downloadable product information, technical data sheets, MSDS and architectural specifications.

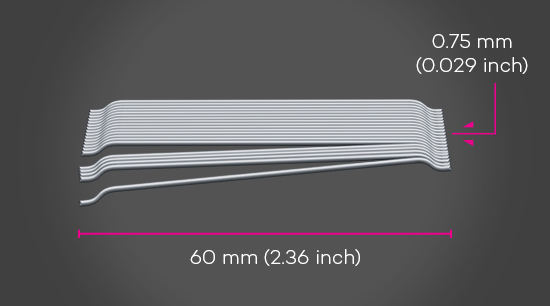

PROFORCE® 80

Supreme Level Hookend Fibre

Downloadable product information, technical data sheets, MSDS and architectural specifications.

PROFORCE 65/60U

Ultra High Premium Level Hookend Fibre

Downloadable product information, technical data sheets, MSDS and architectural specifications.

Projects

Proforce® at work

T&G Packhouse

T&G Packhouse

Inforce is pleased to have partnered with First Principles Constructors (FPC) on another primary sector facility. This project featured a high-capacity apple packhouse, along with a packaging store and amenities block, all thoughtfully integrated to cater to diverse operational needs.

VIEW PROJECTIBEX Lighting

IBEX Lighting

The Ibex developer approached iNFORCE to provide a fit-for-purpose design for this stunning-looking new warehouse and office complex in the fast-growing Tauriko business park in Tauranga.

iNFORCE was asked to review an existing conventionally reinforced floor in another building of theirs where the failed joints and structural cracking had caused significant disruption to their operations through maintenance and equipment damage. iNFORCE provided a floor design that could almost completely eliminate disruptive maintenance. This was achieved by removing all saw cuts in the floor and armouring the control joints with the state-of-the-art Wave joint to create a large clear area for the company’s materials handling equipment.

Simplify Your Concrete

With Confidence.

Do it now.

LET'S TALK

External Slab, Tauranga

External Slab, Tauranga

A heavy-duty slab with high wear requires a pavement design that is fit for purpose.

The design team at iNFORCE worked with the project engineer to provide a jointless external pavement design that was capable of supporting the client’s CVS Ferrari F500.RS2 Reach Stacker with a tare weight of 71,500kg and a lifting weight of 45,000kg.

VIEW PROJECTCool Store Extension, Motueka

Cool Store Extension, Motueka

The iNFORCE team supported the project engineer for this new cool store extension, ensuring Golden Bay Fruit received an optimal slab design solution. The design criteria was simple: meet the load cases as per the specification and minimise joints. After consultation with the project team, we put together a design that would remove sawn joints. Where joints were required, we specified Permaban Wave: an innovative and robust jointing system that would protect the joints, particularly in high traffic areas.

VIEW PROJECTAllied Engineering Developments

Allied Engineering Developments

Inforce worked with Allied Engineering Developments on this new warehouse project using Proforce hook-end fibres in the floor slabs to replace steel mesh reinforcing.

VIEW PROJECTContact

Let's talk

about it

We understand that choosing the correct solution and type of product is essential for the success of any project. Inforce has a technical support team with many years of concrete industry experience and successful project applications and are ready to help you find the right solution for your application.