Swap mesh for fibre and halve your carbon footprint

We’re passionate about optimising concrete slab and pavement designs – not just because they can be made more durable and cost-effective with fibre, but also because there are substantial environmental benefits to be had through optimised designs.

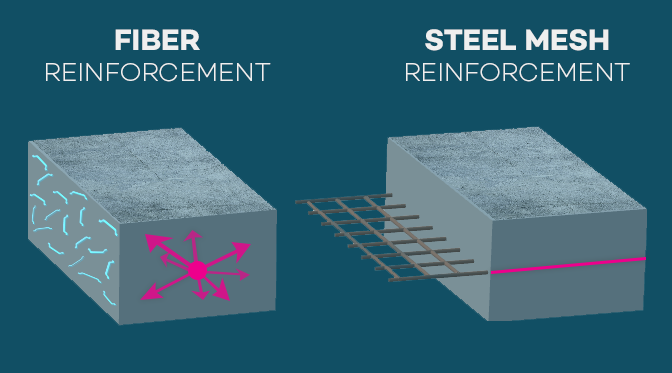

As an example, using fibre in slab on grade projects to replace steel mesh results in better quality designs that minimise waste and have a substantially reduced carbon footprint. Studies have shown that using fibre reinforcement in concrete as an alternative to conventional steel rebar can reduce the carbon footprint of an industrial floor by as much as 56%.

This is due to the reduction in manufacturing and transport emissions when compared to traditional mesh. Mesh is heavy to transport, difficult to handle and time-consuming to set up.

In contrast, fibre reinforcement is only a fraction of the mass of conventional reinforcement, meaning significant reductions in imported shipping and domestic transport. Truckloads of steel mesh reinforcing can be replaced with a small number of pallets!

Contact us to see how we can optimise your slab and pavement designs for strength, cost efficiency and reduced environmental impact.