A concrete floor is often constructed in many panels and the point where one panel meets another is called a joint. Anything on top of the concrete floor applies pressure (or a load) to the slab.

When materials handling equipment (MHE) moves across the floor and approaches a concrete slab joint, the panels need to work together to adequately carry the load applied by the MHE. This interaction between each panel (called the approach and leave slabs) is achieved by load transfer.

Load transfer is considered at joints and cracks in concrete floor slabs and can be defined as the ability for a slab to transfer shear to an adjacent slab.

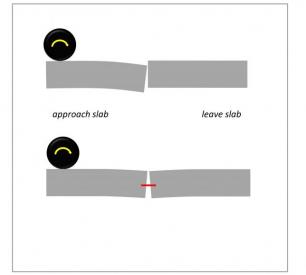

The load transfer ability of a joint or crack has a direct influence on vertical displacement between two slabs. Poor load transfer means that adjacent panels will deflect independently under an applied load, producing an uneven floor which will be prone to damage (see figure 01).

Figure 1. Demonstrating Load Transfer

How is load transfer achieved?

For saw-induced joints, mid-panel load transfer can be provided through aggregate interlock or steel reinforcement.

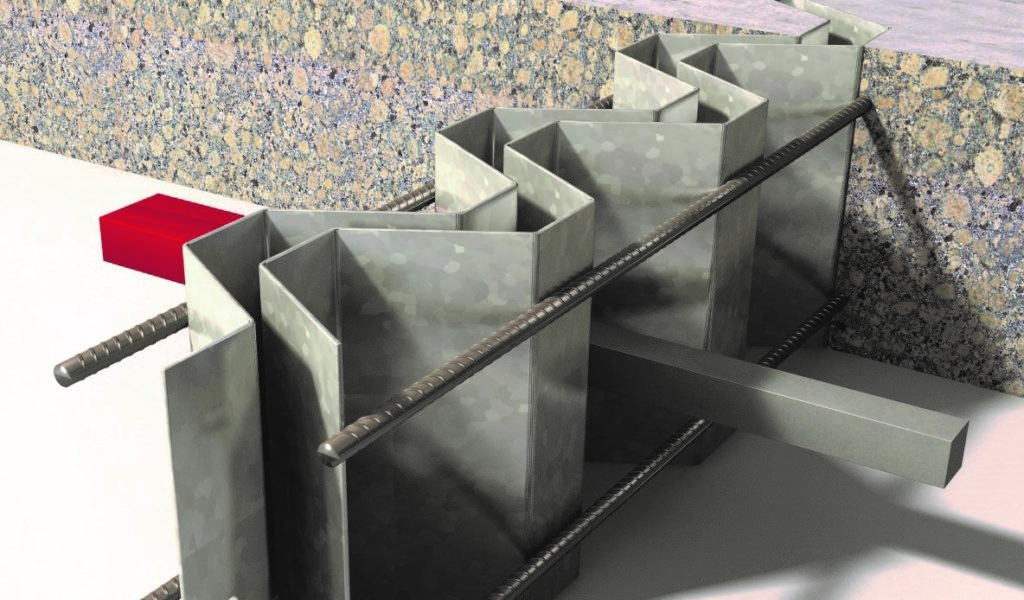

At formed construction joints, load transfer in concrete floor slabs is provided by steel dowels, such as the plate dowels and square dowel bars found within iNFORCE joint products.

How is load transfer calculated?

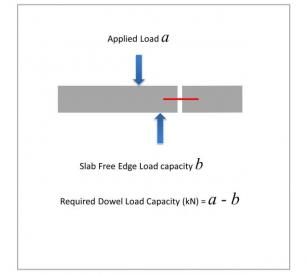

In New Zealand, load transfer capacity is calculated in accordance with TR34, and an ultimate capacity is derived in kilonewton per meter. In accordance with TR34, the required dowel capacity is the difference between the free edge capacity of the slab and the applied load, and not the applied load itself (see figure 2).

An alternative approach is detailed by the American Concrete Institute (ACI). The ACI considers the difference in vertical displacement between approach and leave slabs at a joint, or the deflection across the joint. This is referred to as the load transfer efficiency of the joint.

Research conducted by Permaban demonstrates that both approaches provide directly comparable values for a given joint opening width. Both load transfer efficiency and the ultimate calculated capacity of a joint decrease linearly as the joint opening increases for a constant dowel type.

Figure 2. Calculating Load Transfer Capacity

What factors affect the amount of ‘available’ load transfer at formed construction joints?

The load transfer performance of a steel dowel is determined by:

• the long term joint width

• the type of dowel

• the strength of the concrete used to construct the slab.

Many other factors influence each of these properties – for example the long term joint width is a function of joint spacing and drying shrinkage of the concrete.

For more information about the load transfer of iNFORCE dowels, please speak to our team.

Re published from Permaban. First published December 2013 www.permaban.com