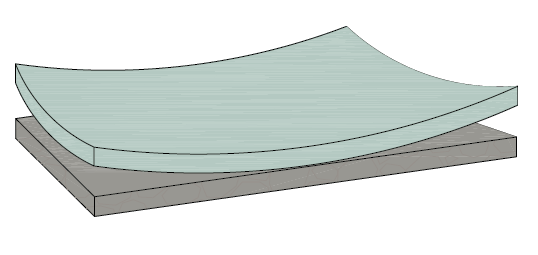

Curling is a phenomenon that occurs in concrete slabs, lifting the edges of them and causes problems such as:

- Level change between slabs, which effect to the passage of vehicles, especially noticeable with small and hard wheels

- Breaks of the slabs when applying loads on the edges, which are literally flown on the base of the pavement

- Worsening of the flatness. The regulations in this point demand to measure in the first hours or days after the execution, nevertheless, a later pronounced curling can make the activity for which that floor was executed be limited or impossible

This phenomenon has a main cause that we know, which is the drying, temperature and differential retraction between the top of the slab with respect to the bottom. It seems evident that concrete drying occurs more quickly on the surface, which causes greater retraction (and, therefore, more volume loss) in the upper layers than in the lower layers, which causes the bow to rise upwards. perimeter.

The intensity of the roll is proportional to this difference in drying, so historically the following recommendations have been given, which, although they are good for reducing the effects of this phenomenon, are or may be detrimental to the appearance of other pathologies:

- Use of mixtures with little water (low A / C): This may imply low workability of the concrete, or excessive use of water-reducing additives, which could cause differences of concrete settings and surface problems, as well as lack of hydration of layers if there any.

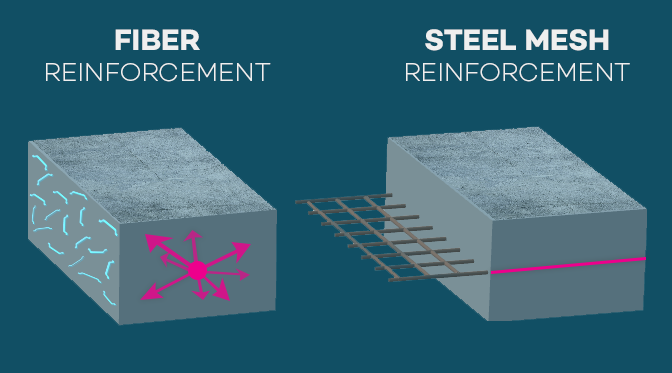

- Use of mixtures with coarser aggregates: This may involve segregation, in addition to weakening the effectiveness of the armed with fibers.

- Use of mixtures with little quantity of cement: It can affect the design resistance, in addition to causing a lack of bonding of superficial rolling layers.

- Avoid using steam barriers: Counterproductive when these are necessary. Let’s not forget that the polyethylene sheets are also a great friction reducer between the slab and the base, which helps the firm work freely, avoiding cracks and other pathologies.

- Use greater thickness of the slab, with the implications in cost that it has.

In addition to these recommendations, which may or may not be used depending on the desired degree of acceptance of these “side effects”, there are other measures that should be used in any concrete slab, since they only have positive effects on both the roll intensity and in other phenomena:

- Good curing of the floor: Whatever the method, it must be ensured that the curing is uniform throughout the slab including its edges and singular points, this will avoid to a great extent differences in drying.

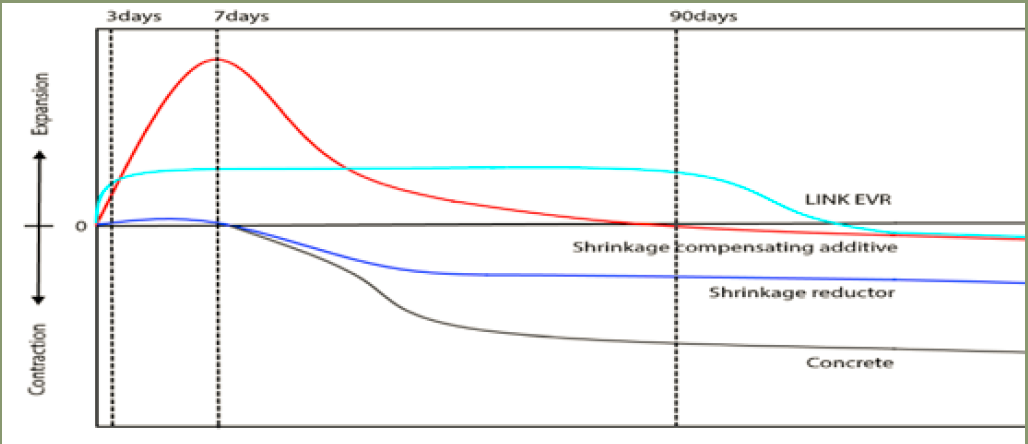

- Use of the volume compensator additive LINK EVR, which is on the market through several systems of the RCR INDUSTRIAL FLOORING group that carry the VRS (Volumetric Retraction Stability) technology. This additive, unlike the compensated retraction concretes (which need large armor to fight against the strong expansion of the first days), generates a moderate expansion in the early stages of concrete (when it is weaker), to end with a slight retraction after 90 days, with the resistance already at its peak.

Republished with permission: https://www.linkedin.com/pulse/curling-concrete-floors-causes-consequences-ramon-planas-masip/